2015

年

公司成立

10

亿

总投资

120

亩

占地面积

99.8

%

产品合格率高达99.8%

WHO WE ARE

江苏澳兰德新材料科技有限公司

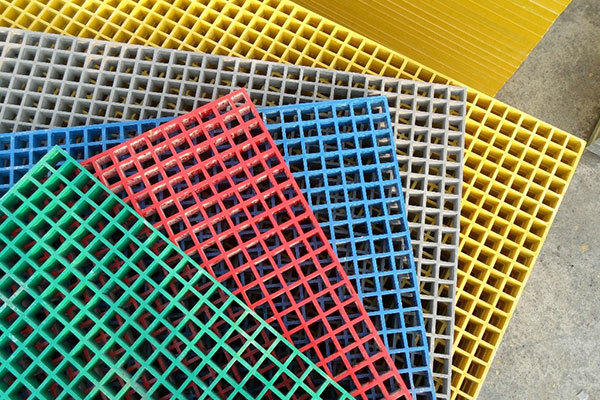

江苏澳兰德新材料科技有限公司是一家集研发、设计、生产为一体的玻璃钢制品专业制造商和销售商。主要产品包括:玻璃钢模塑格栅、玻璃钢拉挤格栅、玻璃钢拉挤型材、玻璃钢模压制品及各种手糊制品等,产品销往世界各地,且在国际市场占有一席之地。

公司位于南通港闸福地费桥工业园区,西有火车站,东邻飞机场,高速公路、苏通大桥、江海港口都近在咫尺。水、陆、空交通十分便捷,有其人流、物流得天独厚的优势。在多年的生产实践中,公司积累了丰富的生产实践经验,确保生产出高品质的玻璃钢制品。产品先后通过了ASTME 一84 防火测试及美国船级社品质认证。在严格品质控管的生产流程下,产品合格率高达99.8%,已通过1S09001 :2008 质量体系认证。

产品优势

RECOMMENDED PRODUCTS

质量保障

多年行业生产加工经验,专业打造源头品质。

防锈耐腐

多年行业生产加工经验,专业打造源头品质。

精密加工

多年行业生产加工经验,专业打造源头品质。

承重力强

多年行业生产加工经验,专业打造源头品质。

工程案例

PROJECT CASE

新闻动态

NEWS

jim@frpcomposites.cn

jim@frpcomposites.cn

13862943095

13862943095